“The goal [of growers] is consistent output. Consistency is not just a function of volume, it’s a function of quality.”

— Darryn Keiller, WayBeyond

From its headquarters on Auckland’s North Shore, WayBeyond develops technology solutions for commercial growers around the globe. Solutions that allow growers to do more with less: to harness new technologies, connect disparate systems and leverage plant and environmental data to optimise farming processes.

The WayBeyond story begins in late 2015 when Darryn Keiller had a vision for the future of global agriculture. According to WayBeyond’s website:

‘This vision was Controlled Environment Agriculture (CEA), combining advanced plant science and the latest technology with an open ecosystem, to provide high yielding and sustainably produced crops. In January 2016, Darryn pitched his vision at an Agritech investor event. Reaction was ambivalent — few understood what CEA even was.’

Six years later, Keiller is recognised globally as one of the pioneers and thought leaders in the CEA sector which is growing at a rapid rate. Investment in the sector is projected to increase from US$2.4 billion in 2018 to US$18 billion by 2026.

CEA is the umbrella term for different forms of farming that includes indoor or vertical farming, protected cropping (crops that are grown outdoors with some protection against the elements — for example, hoop houses, tunnel houses or canopies) and greenhouses. Vertical farming dominates the headlines when it comes to CEA but greenhouses are the most mature category.

Greenhouses range from low tech to high tech where you have a high degree of control over the environment. In New Zealand, there are somewhere between 180 to 250 hectares of commercial greenhouses. Globally there are 500,000 hectares and the sector is growing by up to 10 percent per year. The size of the prize and the complexity of the challenge attracted Keiller to the industry.

“Our focus is almost completely offshore because that’s where the opportunity is,” he says. “We’ve got people on the ground in key markets — for example, Mexico — and we’ve partnered with some great companies in other countries including Vietnam. We’re working with the large multinational corporate growers (MNCs) and the seed and agrochemical giants because they’re trying to solve the same problems we are. These MNCs are a channel to the customer and they’re hugely influential. WayBeyond is closely aligned with these MNCs around where the industry needs to go and how it’s likely to get there and the potential collaboration with these companies is very exciting.”

From dated to data

Keiller’s introduction to the horticulture sector came in 2014 when he started working with Autogrow, a climate computer and farm automation company that develops systems for small-to-medium fresh produce growers to control the growing environment — heating, cooling and so on.

Initially an investor, he was appointed Autogrow’s CEO in 2016 and saw an opportunity to transform the sector. With an extensive career in the business technology sector behind him, Keiller was surprised at how little innovation there was in horticulture.

“I could see a way to harness technology,” he says. “Using technology to solve problems is something I understand really well. When I first started, growers were essentially farming the same way they had for the last 100 years. There was no significant investment in robotics, Artificial Intelligence (AI), or data.”

“The thing is, robots are not the answer for many farmers. Apart from the huge conglomerate growers, most operations, in New Zealand and globally, are not set up to optimise that type of advanced technology. They need an alternative way to increase yield and productivity.”

Folium is WayBeyond’s climate monitoring system that analyses the temperature, humidity, radiation and carbon dioxide (CO2) levels in a greenhouse, giving growers a comprehensive overview of the microclimate and optimal growing conditions. Plant sensors monitor the physiological response of the plant to the environment, nutrients and other inputs.

Traditionally, growing decisions were largely based on the farmers’ expertise and intuition. Now, the data supports the grower to make more informed decisions based on science and technology.

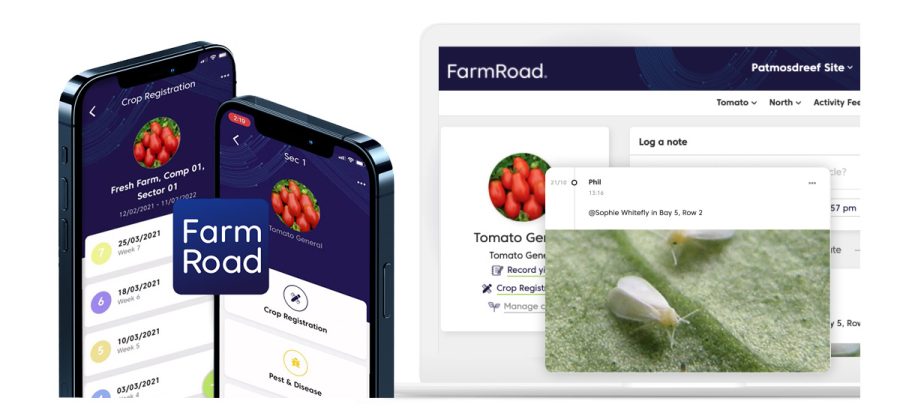

The company’s FarmRoad crop management software enables growers to bring together all of their farming data in one powerful, unified, and easy-to-use platform.

Knowledge is power

“We’re creating a knowledge based system for farmers,” says Keiller. “Our technology is based on a framework developed by the plant research industry: Genetics x Environment x Management (GxExM). Those are the three big levers you can pull to optimise a crop.”

“Currently, there’s no silver bullet for more predictable and stable yields because of the complexity involved in trying to control these different levers. The goal is consistent output. Consistency is not just a function of volume, it’s a function of quality.”

“The big challenge for the horticulture industry is quality control. If you’re growing apples, oranges, kiwifruit, or whatever, the grower wants to be able to regulate outlier events that impact quality. For a premium fruit or vegetable, you get anywhere from three to five times more dollars per kilo than you do for second grade output.”

“We’re moving from gathering and analysing data to prescribing solutions. You can take a photo of a plant and the system will give you feedback on what it needs. Then you will be able to start looking at patterns and predictions to avoid pest outbreaks for example. That will also allow us to advise growers on more sustainable and environmentally friendly practices using data and AI.”

“It’s what distinguishes us from a lot of other companies that are focused on the mechanistic control layer. We’re all about that knowledge-based, AI, learning layer. That’s what we’re placing our bets on because if we get it right it will really change the game.”

“I would never have embarked on this journey if I wasn’t absolutely convinced that there was an opportunity to lead positive change in the food system. There’s still a massive gap between where the industry is today and what it will look like in the very near future but that’s why we’re doing this.”

WayBeyond’s ultimate goal is to develop virtual agronomists using an interactive system that is smarter than the grower. Farmers won’t need to worry about all the different environmental factors and inputs needed to produce high yield, high quality fruit and vegetables because the WayBeyond system will have all the data necessary to optimise production.

“Once you’ve got data from all these farms around the world you can start asking questions like: “Why does this crop on this farm in this country perform better than the same crop in a different environment?” says Keiller. “The data will give you the answer and the optimum conditions necessary to consistently produce high quality fruit and vegetables at the lowest possible cost. The goal is better crop outcomes with less inputs so that farming is more sustainable and efficient.

WayBeyond is not only committed to making individual farmers’ lives easier, the company has a bigger goal in mind. The data from farms around the world will enable growers to tackle the big issues like labour, water and energy optimisation.

Going global

Agritech entrepreneurs in New Zealand have to deal with what Keiller calls ‘the tyranny of distance.’

“The other centres of Agritech innovation around the world including Israel, the Netherlands, Belgium and certain parts of the USA, have easy access to corporate growers, willing partners and massive markets,” he says. “They’ve got access to more capital and so when they roll out a new piece of technology it can scale really quickly. Trying to do that from New Zealand, you’re up against it.”

“One of the first challenges is how do you get people to know who you are, what you’re doing and why it matters. To do that, you’ve got to get out into the world. You’ve got to be present at the big trade events. You’ve got to meet customers in the flesh to build strong relationships. You’ve got to visit farms and talk to the growers to learn what their real problems are. You’ve got to hustle. We launched WayBeyond in the pandemic so getting overseas to do that kind of work has been a huge challenge.”

Another challenge is the fact that farming and horticulture are typically conservative, risk averse industries.

“You build something that works, that is innovative and potentially game changing and you think, ‘Well, of course companies will want to buy it,’” says Keillier. “But usually they will want to trial it over an entire season which is a long time. You’re talking nine months to a year before the customer feels confident in what you’re selling before they’re prepared to pay for it. By that stage you’ve invested a lot of money in developing and building the product and you’re burning cash all the time. So you’ve got to be patient and be prepared for it to take longer than you think.”